利欧集团

29 年

公司成立200 +

2022年营业额达(亿元)5亿 +

全球用户信任之选150 +

品牌授权代理国家及地区15000 +

全球销售服务网点新闻中心

利欧集团董事长新春贺词|三十而立 逐光而行

2024.02.18

凝心聚力,共赢致远 | 利欧泵业召开2023年度总...

2024.01.31

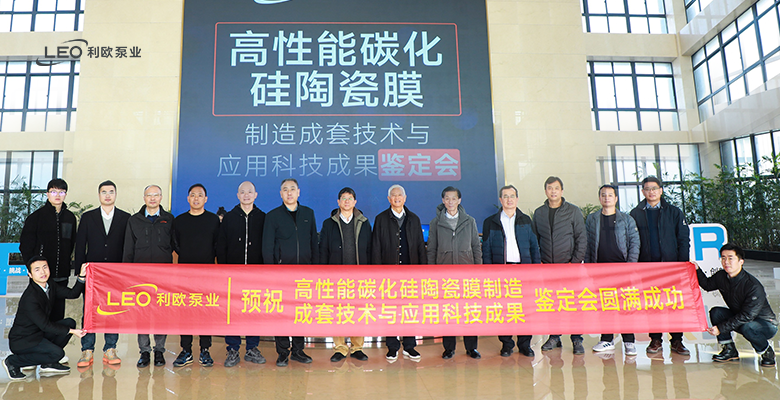

利欧与浙理工共研的“高性能碳化硅陶瓷膜”通过高从堦...

2024.01.17

利欧集团董事长王相荣2024元旦致辞

2024.01.05

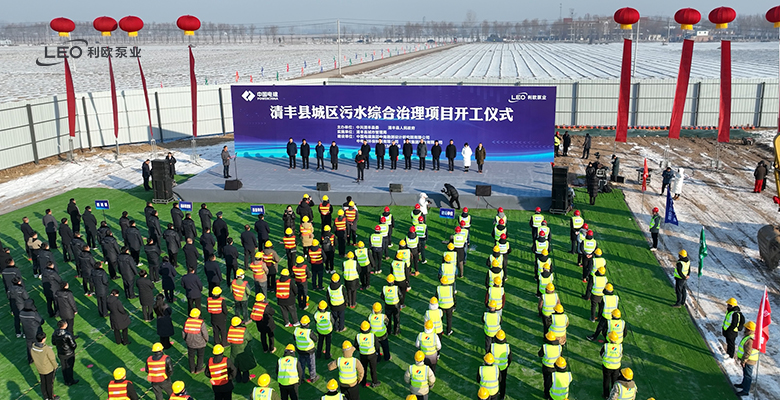

总投资约8.7亿!利欧泵业、中国电建中南院联合体中...

2023.12.26

共生美好 | 利欧泵业全国39地办事处焕新升级,打...

2023.11.23

浙理利欧流体机械校企融合发展研讨会暨合作成果发布会...

2023.09.19

遥遥领先!以荣誉 证实力!

2023.09.15

利欧集团2024届全球校园招聘正式开启:泵造未来,...

2023.09.01

重磅!利欧集团与沙特投资部签署战略合作备忘录

2023.06.13

共赢!利欧与浙江理工大学签订科技合作协议,捐赠能源...

2023.05.24

媒体专访 | 浙江之声对话利欧泵业,听利欧的智慧水...

2023.05.18

浙商专访 | 利欧集团董事长王相荣:构建智慧流动的...

2023.05.09

第一财经专访利欧 | 泵业隐形冠军,深挖内循环潜力

2023.02.08

利欧为卡塔尔世界杯提供智慧用水解决方案!

2022.11.17